Key Takeaways:

1. Tackle Twill Offers Premium Durability

Tackle twill uses stitched fabric pieces for a bold, raised design that is highly durable, ideal for jerseys and varsity jackets.

2. Versatile for Many Apparel Types

It’s used beyond sportswear, adding a textured, premium look to hoodies, jackets, and accessories like bags.

3. Kustom Imprints Delivers Expert Quality

Kustom Imprints specializes in tackle twill, offering precise, customizable designs with professional craftsmanship.

What Exactly IS Tackle Twill?

Imagine creating a design not by stitching it directly onto the garment piece by piece, but by cutting out shapes or letters from special fabric layers and then sewing those layers onto the base garment. That, in essence, is tackle twill.

Here’s a breakdown of the typical process:

- Design & Digitization: The process starts with your artwork. This design is digitized to map out the shapes (letters, numbers, logos) that need to be cut and plan the crucial sewing paths.

- Material Selection: The “twill” refers to the sturdy polyester or poly-blend fabric with a characteristic diagonal weave used for the appliqué shapes. Multiple colors or even felt can be used for layered or textured effects.

- Cutting: A precision cutter (laser or blade plotter) accurately cuts the design elements from the chosen twill fabric.

- Placement & Adhesion: The cut twill pieces are carefully positioned on the garment. A heat-activated backing or temporary adhesive holds them precisely in place for sewing.

- Sewing: This defines tackle twill. An embroidery or sewing machine stitches around the edges of the twill pieces, typically using a zigzag stitch or a satin stitch, to permanently affix them, provide a clean edge, and prevent fraying.

- Finishing: The garment is inspected, trimmed, and possibly pressed for a final crisp appearance.

The result is a raised, multi-dimensional design that feels substantial and looks incredibly professional, with tangible texture and depth.

Endless Applications: Where Tackle Twill Shines

The versatility of tackle twill extends across a surprising range of apparel:

- Sports Jerseys: The quintessential application for bold numbers, player names, and team crests (Baseball, hockey, football, basketball).

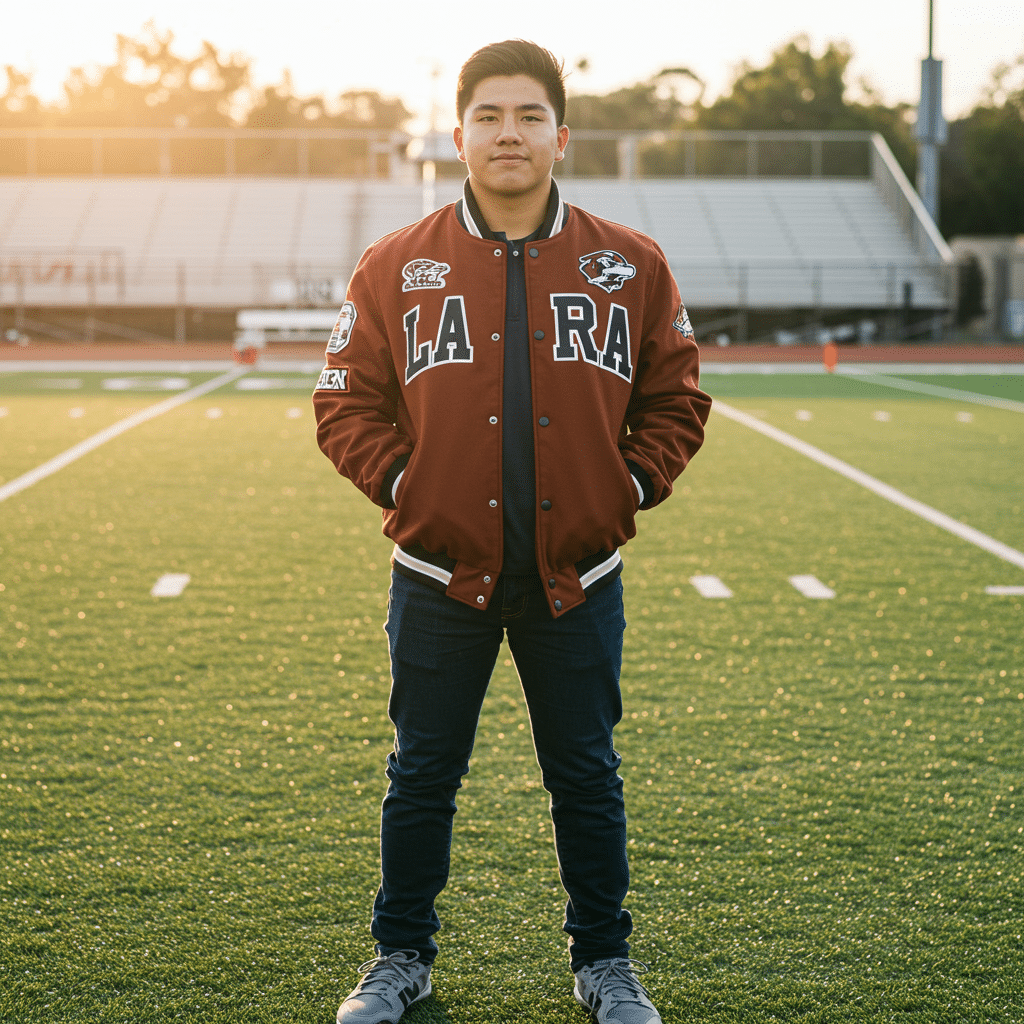

- Varsity Jackets: Often combines chenille patches with tackle twill for sleeve numbers, graduation years, or back lettering, contributing to its timeless appeal.

- Hoodies and Sweatshirts: Perfect for collegiate spirit wear, alumni gear, club sweatshirts, or corporate apparel needing a classic, enduring look.

- Heavyweight Jackets: Adds class and resilience to workwear, coach jackets, and fashion outerwear.

- Bags and Accessories: Provides durable, high-impact logos or identifiers on duffel bags, backpacks, and even banners.

Creative Tackle Twill Ideas: Beyond the Basics

While the classics are great, let’s brainstorm some unique ways tackle twill can make a statement:

- The “Pink Ladies” / Greaser Gang Jacket: Remember Grease? Recreate that vibe for a modern group (bowling team, car club, bachelorette party) using custom jackets (satin, bomber, denim) with the group’s name or symbol in bold, potentially layered, tackle twill for that standout retro look.

- The Classic High School/College Varsity Jacket: Personalize this staple beyond the standard letter and year. Add custom tackle twill patches for specific achievements (“State Champs,” “Debate Club President”) or nicknames.

- The Boutique Band Merchandise: Elevate band merch by offering premium hoodies or denim jackets featuring the logo or album art in tackle twill. It becomes a coveted fashion item, justifying a higher price and creating a stronger fan connection.

- Commemorative Fraternity/Sorority Gear: For anniversaries or special events, tackle twill Greek letters on high-quality sweatshirts or jackets create a lasting symbol of brotherhood/sisterhood that feels more substantial than print. Layered twill in chapter colors is especially effective.

- Artistic Fashion Pieces: Imagine limited-run jackets featuring large, abstract shapes or stylized text applied using tackle twill, perhaps mixed with other textured fabrics, moving it into the realm of wearable art.

Tackle Twill vs. Embroidery: Understanding the Difference

Many customers weigh tackle twill against its closest cousin: embroidery. While both involve thread and sewing machines, they differ significantly.

Embroidery: Stitches a design directly onto the fabric using thread.

- Pros: Great for fine detail, smaller logos, text. Can create complex multi-colored designs. Often cost-effective for smaller or detailed designs. Offers a classic, professional look.

- Cons: Large embroidered areas can become dense and stiff. High stitch counts for large fills can be costly and time-consuming. Lacks the bold dimension of tackle twill.

- Cost: Generally less expensive than tackle twill for standard logos/text. (For quality, affordable embroidery, see Kustom Imprints’ services: https://kustomimprints.com/embroidery-shop-in-orange-ca/).

Tackle Twill: Sews pre-cut fabric pieces (twill) onto the garment.

- Pros: Creates a bold, raised look. Excellent for large letters/numbers (jerseys, varsity). Extremely durable. Covers large areas without excessive stiffness. Premium, classic athletic aesthetic.

- Cons: Not suited for very fine details within the appliqué itself. More labor-intensive (cutting, placing, sewing).

- Cost: Generally more expensive than standard embroidery due to material costs and the multi-step process.

The “Luxury” Appeal: Why Tackle Twill Feels Premium

Compared to simpler methods, tackle twill embodies characteristics associated with higher-end goods:

- Material Substance: The twill fabric adds tangible weight, texture, and quality feel.

- Labor-Intensive Craftsmanship: The process requires skill in cutting, precise placement, and clean edge stitching, feeling more constructed than mass-produced.

- Durability and Longevity: Built to withstand washing and wear, tackle twill holds its structure exceptionally well. This inherent quality contributes to its premium status – it’s an investment.

- Bold Aesthetics: The clean lines, raised profile, and layered colors offer strong visual impact, looking intentional and professional.

- Heritage and Tradition: Its link to iconic garments like baseball jerseys and varsity jackets evokes nostalgia, achievement, and classic style.

When is Tackle Twill the Right Choice?

Certain scenarios make tackle twill the clearly superior, often desired, choice:

- Authentic Sports Apparel: Essential for replicating the look and feel of pro or collegiate jerseys.

- Commemorative Items: Elevates garments celebrating milestones or achievements into lasting keepsakes.

- High-Impact Branding: Makes a stronger, more established statement for logos on premium apparel.

- Items Requiring Extreme Durability: Ideal for heavy wear items like team practice gear or work jackets.

- Creating Heirlooms: The enduring appeal and physical longevity needed for items like varsity jackets.

Kustom Imprints: Your US Source for High-End Tackle Twill at Guaranteed Low Prices

Finding a provider who executes high-quality tackle twill within the US might seem challenging or expensive. Kustom Imprints, in Orange, California, excels here.

- US-Based Production: Ensures higher quality control, faster domestic turnarounds, easier communication, and supports the local economy.

- Expertise & Technology: They possess the precision cutting equipment, advanced sewing machines, and skilled team necessary for flawless tackle twill application.

- High-End Results: Kustom Imprints delivers the premium product clients expect, using durable materials and meticulous craftsmanship.

- Guaranteed Low Prices: Leveraging experience, efficiency, and volume purchasing, they offer competitive pricing, making this premium method accessible without sacrificing quality. Their value proposition combines high-end results with affordability.

- Versatility: Capable of handling diverse tackle twill projects, from authentic jerseys to unique custom pieces.

Conclusions

The Final Word: Elevate Your Apparel with Tackle Twill

Tackle twill offers a unique blend of durability, dimension, and classic style. It transforms garments into something substantial and memorable. While embroidery has its place for detail, tackle twill stands apart as the premium option for bold, lasting designs – an investment in quality, impact, and longevity.

If you seek apparel that truly stands out and carries a legacy of quality, consider tackle twill. For expert execution in the USA at a price that respects your budget, connect with the skilled team at Kustom Imprints in Orange, CA. They have the tools, talent, and dedication to bring your tackle twill vision to life.

Frequently Asked Questions

Imagine creating a design not by stitching it directly onto the garment piece by piece, but by cutting out shapes or letters from special fabric layers and then sewing those layers onto the base garment. That, in essence, is tackle twill - it's a raised, multi-dimensional design that feels substantial and looks incredibly professional, with tangible texture and depth.

It is more expensive than screen printing and embroidery because of everything that is involved to make it.

Yes. Call us to talk about any other competitor price you've gotten, and we will meet or beat their price. Call us now 1-800-683-5854 or email [email protected].

Authentic Sports Apparel: Essential for replicating the look and feel of pro or collegiate jerseys. Commemorative Items: Elevates garments celebrating milestones or achievements into lasting keepsakes. High-Impact Branding: Makes a stronger, more established statement for logos on premium apparel. Items Requiring Extreme Durability: Ideal for heavy wear items like team practice gear or work jackets. Creating Heirlooms: The enduring appeal and physical longevity needed for items like varsity jackets.

Embroidery: Stitches a design directly onto the fabric using thread. Tackle Twill: Sews pre-cut fabric pieces (twill) onto the garment.